(WO) The offshore wind industry is projected to produce 228 GW by 2030, enough to power over 68 million homes. These projects will be at greater water depths and with larger wind turbine generators. Therefore, there is a demand for innovative solutions to deliver these projects.

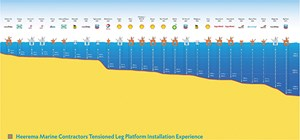

Earlier this year, Heerema Marine Contractors introduced a novel floating wind installation method, designed to upscale the commercialization of offshore floating wind. The company is familiar with installing floating offshore structures, with around 70% of the world’s tension-legged platforms (TLPs) installed by Heerema. The marine contractor has installed approximately 70% of the world’s tension-legged platforms.

These vertically moored floating structures enabled offshore oil and gas production at greater water depths, with the deepest installation being the Big Foot platform in 1,580 m (5,184 ft). Heerema developed innovative, proven installation methods for floating TLP installations, and has built on this knowledge and experience with the floating-to-floating offshore wind installation method.

Floating wind. Offshore floating wind will be essential for the world’s energy transition, but methods under development can be costly, time-consuming, and ultimately may prevent the commercial upscaling of this new frontier in offshore wind.

Appreciating the logistical challenges for deployment at scale, Heerema Marine Contractors developed its new method for offshore floating wind installations to best serve the offshore wind market. The company notes that its significant experience in the complexities of installing floating structures offshore guided the development of this method. Heerema approached the development of the new Floating to Floating installation method with the following goals in mind:

How can the levelized cost of energy in offshore floating wind be reduced?

What can be done to improve schedule robustness and duration?

How can Heerema remove bottlenecks in the supply chain?

Floating to floating installation method. The company’s floating to floating installation method was developed to deliver solutions to industry challenges, such as efficient use of resources like steel and port infrastructure, and offshore logistics and maintenance, while reaching the required scale and rate of installation. The method also utilizes the unique capabilities of Heerema’s fleet of crane vessels, which operate globally and ensure flexibility and versatility on offshore installation projects.

The primary focus for offshore wind developers is to reduce the levelized cost of energy (LCOE), which is an indicator for the price of electricity required for an offshore wind farm project’s revenue to equal costs. The most critical driver for LCOE reduction is increasing turbine size and building wind farms at deeper water depths, where the wind is stronger, while novel methods like Heerema’s will be essential for delivering floating wind farms in the most efficient and cost-effective way.

Currently, there are various proposed methods that involve assembling floating foundations (floaters) in port before wet-towing to the field. This presents logistical challenges, as well as there being pressure on the number of suitable existing harbors.

Therefore, Heerema has developed an alternative method that does not require a wet-tow and removes the need for marshalling yards. Using the floating-to-floating installation method, floaters can be constructed on land before being dry-towed on a transport vessel to the location. After arrival, they will be installed, using Heerema’s floating installation frame to lift the floaters from the vessel, Fig. 2. After that, they will be installed on location. Heerema’s floating installation frame will submerge the floaters down by weight, removing the need for high-tech ballasting or tensioning systems and reducing installation duration, Fig. 3. The bottom foundation work can be executed in parallel by optimizing the capabilities of Heerema’s semi-submersible crane vessels.

Jeroen van Oosten, chief commercial officer said, “We want to show an alternative solution for installing offshore floating wind, especially targeting some of the bottlenecks for scaling up. We strongly believe that by opening up to new ways of working and collaboration, floating wind can reach the potential the industry is looking for.”

Deep dive into benefits. The goal is to lower engineering, procurement and construction costs. The floaters’ volume and weight are reduced by removing the need for wet-towing. Also, the floater is lifted directly from the transportation asset in the field, which means both the floater and wind turbine generator can be optimized for in-place conditions only. A low-tech floater design is possible by integrating installation requirements, such as ballasting provisions, into reusable installation tooling, removing the requirement to build these functionalities into each floater.

Reducing transport costs, requirements. By efficiently using space onboard transport vessels to deliver multiple floaters directly from the fabrication yard to the offshore wind site, transport and marshalling costs are reduced significantly. By removing the need for in-port assembly of the floater and WTG, there is less space and draught required in the port and quayside capacity is reduced, which helps avoid one-off mega-investments in port areas.

Ensuring higher, more efficient and predictable field delivery. By removing time-consuming and highly weather-sensitive wet tows and mooring connections, higher throughput can be achieved on floating wind projects. Heerema’s floating to floating installation method means floater and WTG campaigns can be decoupled, reducing supply-chain pressure, and resulting in a more efficient process.

The crane-supported floating to floating installation method is built on proven technologies from the oil and gas floating platform industry. It allows the saving of tons of steel per floater and will reduce overall project CAPEX.

Future outlook. Heerema continues to invest in the development of installation methods that will enable the offshore wind market to continue to grow and deliver the energy needs of the future. Later this year, the company will use its Rotor Nacelle Assembly (RNA) method to install wind turbine generators for the first time. The RNA installation method avoids all interaction with the seabed, by utilizing Heerema’s Thialf (Fig. 4) to assemble the wind turbine generator components on the vessel’s deck. After the pre-assembly onboard, the turbine will be installed on the foundation. While bolting the turbine on the foundation, the next turbine assembly will commence.

This project can be seen as an important first step in unlocking the installation methods required for floating offshore wind. It will demonstrate the capabilities of Heerema’s floating crane vessels and will be an important milestone for new developments within the offshore wind market.